The pulverized pulverized coal pulverized powder of our pulverized coal pulverized powder forming machine is used as a raw material, and then pressed into carbon rods and carbon blocks by stirring. Our hydraulic molding machine can easily change the mold to produce honeycomb coal with different diameters and different numbers of holes. By changing the mold, it can process cylindrical, square, rectangular, trapezoidal and other finished products. Our molding machine can not only make briquette, but also can be used for kaolin molding, cow dung molding, charcoal powder blue charcoal powder barbecue charcoal molding.

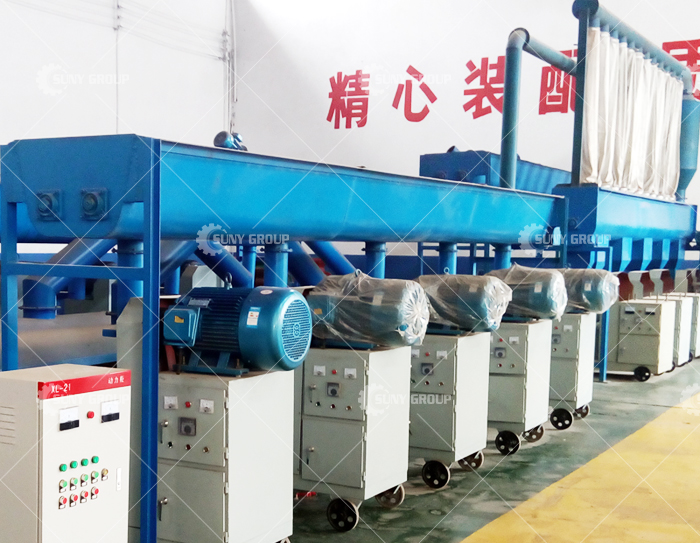

Our hydraulic charcoal machine is composed of main machine, hydraulic pumping station, control cabinet, storage feeder and brick conveying:

1. The main machine consists of upper and lower beams, sliders, mold frames, molds, and columns. The upper and lower beams, sliders, and mold frames are made of high-quality cast steel, which has high strength, low processing costs, and can be used for a long time without deformation or cracking. Using 45 # steel, the surface is plated with hard chrome, which has the advantages of wear resistance and no rust. The mold is customized by a professional mold factory with high precision and wear resistance. The service life is 2-3 times that of ordinary molds.

2.Hydraulic pump station consists of hydraulic pump, hydraulic valve block, fuel tank, cooler, filter, motor, pressure gauge, etc. The quality of the hydraulic valve and hydraulic pump determines the quality of the refractory brick forming hydraulic machine;

3. The control cabinet is used to control the host and the hydraulic pump station, and sends signals through the PLC programmable controller to control the movement of each component;

4.The storage feeder is used to store the mixture and to quantify the mixture to the host hopper;

5.The flat conveying of the charcoal block is used to convey the charcoal released from the mold.

The hydraulic carbon rod forming machine can also be called a punching rod making machine, which is a carbon rod with a central hole (usually a four-corner and hexagonal shape) that is punched through a high-pressure process after carbonization and crushing of bamboo, wood, nut shells, and other materials. Rod-shaped), the machine parts are made of special wear-resistant material formula, precision casting, durable; the fit, compactness and wear resistance between the propulsion shaft and the inner sleeve have been greatly improved. The new carbon rod forming machine has the advantages of high output, low energy consumption, compactness and durability. The diameter of the finished rod ranges from 3-10cm, which provides a guarantee for making high-quality charcoal.

Zhengyang Charcoal Machine Home Page: http://www.zyfuelmachine.com/,All rights reserved.