Briquette making machine is the use of a screw extrusion principle. Charcoal briquette machine compress the modulated coal powder into a predetermined shape with a certain strength, which can instead of burning coal and coal gas with the higher economic efficiency.

The briquette process can be the following steps:

1. Get the raw material crushed.

2. Put crushed biomass into carbonization furnace for anaerobic carbonization, and the organics, tar and moisture contained in the biomass are all carbonized during anaerobic firing process. After cooling, users can get charcoal powder.

3. Then transport charcoal powder into grinding wheel mixer for fully mixing and wetting.

4. Put the mixed charcoal into different charcoal briquette machine to get charcoals of wanted shapes.

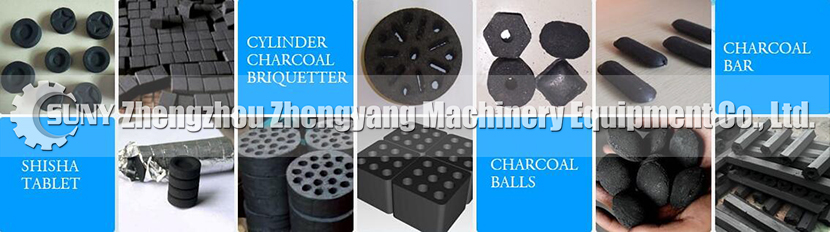

Briquette making machine make charcoal and coal powder into charcoal briquette. It can make many different shape and size, such as charcoal tablet, charcoal bar, charcoal ball, etc.

Zhengyang Machinery is a professional recycling equipment manufacturer. The charcoal production line and charcoal briquette making machine have been exported to Russia, Uzbekistan, Myanmar, Vietnam, Laos, Kazakhstan and many African countries. For more information, please contact us or leave a message.

Zhengyang Charcoal Machine Home Page: http://www.zyfuelmachine.com/,All rights reserved.